Our journey into electronics manufacturing services

How did we expand our business to offer bespoke Electronic Manufacturing Services? For us, it started with a single question — and a client in need. Here’s how we turned one challenge into a long-term capability.

At Eurobase, our business has never been about chasing trends or ticking boxes — it’s been about listening. Since day one, we’ve built our company by tuning into what our customers need, identifying where we can add value, and evolving with purpose.

So, when people ask how a company rooted in logistics and supply chain management became a trusted partner in Electronic Manufacturing Services (EMS), the answer is simple: we followed the need.

It all started with a question

Back in 2000, one of our long-standing US clients approached us with a pressing issue. Their European contract manufacturer had suddenly ceased operations, leaving them without a critical supplier for electronic assemblies – components that were essential to their ability to serve customers across Europe.

After months of searching for a suitable replacement, the client turned to us. “Can Eurobase help?” they asked.

We weren’t electronics manufacturers – not yet. But we were problem-solvers. And more importantly, we had the infrastructure, the supply chain expertise, and a deep

Steep learning curve — and a turning point

Entering the EMS sector was a leap. We were stepping into a highly technical, quality-critical industry with little margin for error. But as with everything we do, we leaned into ti with focus, care, and humility.

We learned fast. We invested in the right systems, people, and processes. We collaborated closely with our client, treating their challenge as our own. And slowly but surely, we didn’t just meet expectations – we exceeded them.

What began as a one-off solution became a scalable, reliable service that we could offer to other clients.

25 years on: EMS as a core capability

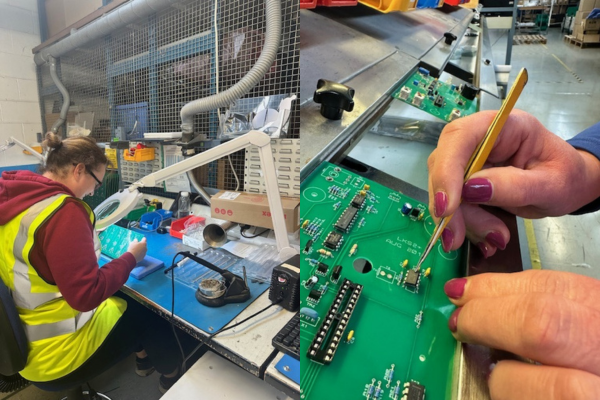

Today, our EMS capability has evolved into a trusted, full-service offering, servicing industries from EV charging and LED lighting to agritech, measurement, and monitoring technologies.

From sourcing components and managing supplier relationships to precision manufacturing, quality assurance, and distribution, we offer end-to-end tailored solutions. This integration means our clients can focus on what they do best, while we take care of the complexity.

Our journey into EMS wasn’t driven by expansion for expansion’s sake. It was driven by the same values that have always defined us: responsiveness, collaboration, and commitment to quality. As technology advances and industries continue to shift, we remain committed to continuous improvement. We’re embracing new tools, smarter systems, and more sustainable practices – and we’re just getting started.

Interested in chatting with us about our EMS capabilities?